Benefits of a seamless food supply chain

Supply chains are only as strong as their weakest link, and when one partner doesn’t pull their weight the entire chain suffers. That’s why a seamless and synchronized supply chain is essential to an efficient and successful business. Utilizing a supply chain solution to connect each partner together helps to ensure that your network operates at its best.

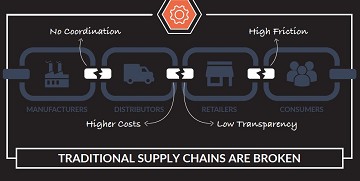

A disconnected supply chain is inherently inefficient, as partners are lacking important data necessary for eliminating waste. These inefficiencies can add up to significant costs, money which could better be utilized to grow your business. This disconnect can also lead to errors in shipping, which leaves you without the product you need.

Consider an instance where food products you purchase are being recalled throughout your area due to contamination. In a disconnected supply chain, the news of the recall reach you within the first days of the recall, but there is limited news or information available. Your supplier cannot confirm whether or not your shipment was tainted, and this uncertainty means you have to act as though your food is contaminated. By throwing out your stock, you are unable to service your customers with the food items they like most. Weeks later, once the source of the contamination is confirmed, it becomes clear that your food supply was not contaminated in the first place. A disconnected supply chain means that your supply chain wasted stock, and missed out on revenues needlessly.

When supply chains become synchronized, visibility increases across partners and everyone benefits. Increased visibility means clear definitions of roles with limited overlap, reducing inefficient practices between partners. Synchronization also decreases order errors, meaning your products arrive when and where you need them to. A connected supply chain also helps to better regulate product safety and has an increased reaction time in the event of contamination.

In the same hypothetical as before, there is a recall on a certain food item which you purchase. Within seconds, the recall information arrives to you via your shared software with your supplier. Because your supplier is also synchronized with the producers, they are able to leverage this synchronicity to identify which shipments are at risk. This time, your supplier is able to notify you that the contamination risk is only present in shipments 1-4 and you received shipment 8, and therefore your products are safe to use. Here, your supply chain is able to adapt and react quickly to updates and avoids the unnecessarily wasted product.

Synchronized supply chains arise when every partner is able to openly communicate with every other partner. This means that information must flow easily from the producer or manufacturer to the retailer, and vice versa, and it must do so quickly. In many cases, this involves using shared software to ensure data moves seamlessly and immediately between partners. It also requires a clear definition of roles and expectations that each partner holds, to ensure that partners can remain accountable to themselves and to each other.

Get in touch: Routeique Inc.

routeique.com

sayhi@routeique.com

+1 (587) 318-7865

Follow us

TWITTER: @routeique

FACEBOOK: Routeique

LINKEDIN:/company/routeique